How To Measure For A Kitchen Splashback.

It is important to get the perfect measurements prior to ordering your splashback, to avoid any issues occurring when fitting. To make things easier for you, here’s our step by step guide to help you achieve the perfect fit. Ig you are still unsure you can order one of our Splashback Templates.

Step One

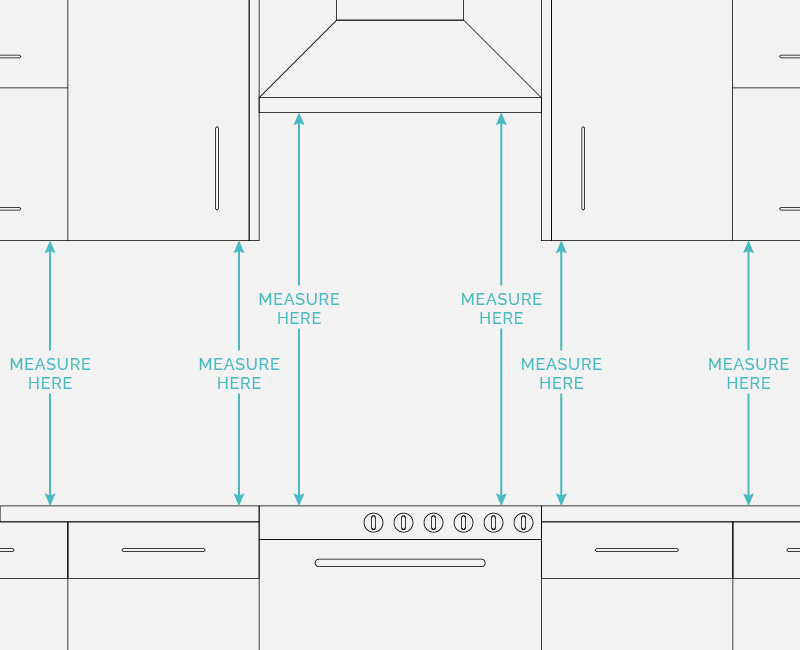

If you have any obstacles such as kitchen cupboards or extractor fans, take more than one measurement as you can not rely on obstacles always being 100% level. We then recommend using the shortest measurement of the two.

Step Two

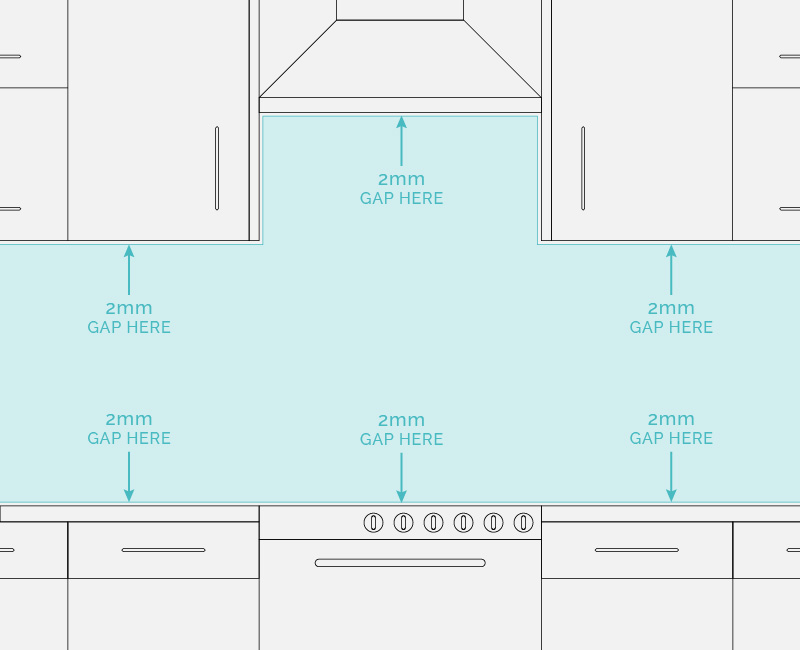

You must also take into account expansion, this is the reason why we recommend using the shortest measurement. If the splashback is a tight fit then this will make it expand and crack with heat. We advise a 2mm heat expansion gap, this is deducted from each edge that the splashback meets an object or wall.

Step Three

When fitting, spacers can be used to give the correct positioning on each edge. Once the sealant has dried and the splashback has been properly fitted, simply remove the spacers and apply the appropriate sealant along the gap.

a. If 2 panels are being joined together leave a 4mm gap between the two when fitting.

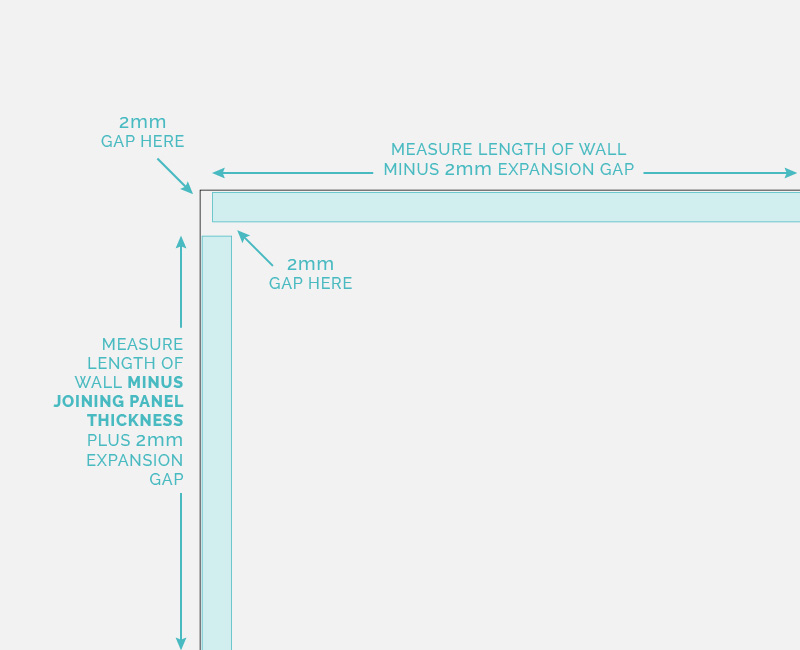

b. If you are fitting a splashback that will need to feature corners, we advise that your measurements leave approximately 2mm per panel for expansion and also deduct the thickness of one panel (approx 5mm for acrylic and 6mm for glass) where they intercept at the corner. The gap where the two panels meet can then be silicone sealed (solvent-free) after fitting.

Step Four

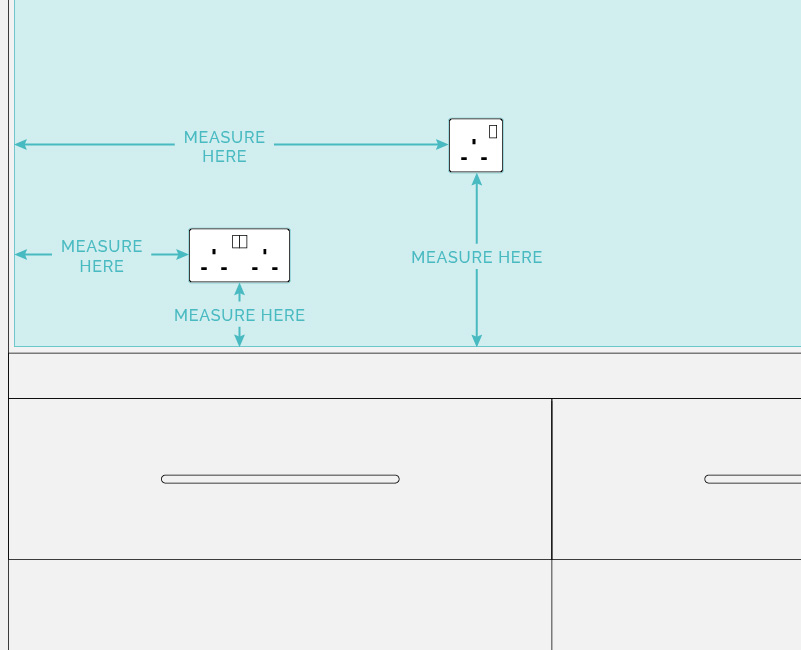

Finally, when measuring socket cutouts we will need the height from the base and side as shown in the diagram. Please measure to the outside of the socket, and also supply us the socket size separately. Don’t forget to factor in the 2mm expansion gap when measuring for your cutout. When we cut the splashback, we will cut the socket hole 10mm smaller overall which means your socket will sit on top of the splashback giving a seamless finish. It always helps to upload your sketch, this can be done when socket cut outs or panel cut outs is selected on the product page.

PLEASE NOTE: If you have an induction or electric hob, you can have a continuous acrylic splashback, so long as there is a 200mm gap between the hob and the panel. If you have a gas hob, you will need to purchase a glass splashback for that particular area. If you require more than one panel you can add each individually to your cart on our site. For ACM (Aluminium composite) splashbacks, there should be a 150mm gap between the splashback and the heat source. The information in this guide is designed to act as a reference. It is advised that you double check all measurements thoroughly before submitting them to our site. Custom Splashbacks will not accept liability for any errors caused by inaccurate measurements.